X-Ray Inspection

X-ray inspection can be a very effective and non-destructive type of analysis. This form of interactive radiography provides internal viewing of an assembly’s design, internal components, workmanship and potential latent quality issues. Digital X-ray technology has added a new dimension to X-ray inspection that extends beyond traditional film-based cabinet type technology, including the use of specially devised algorithms for void analysis.

The term “digital” in digital X-ray refers to the technology of image acquisition where the data is collected or transferred to electronically stored media. Digital radiography detector technologies such as image intensifiers and solid-state panels can vary in size and pixel count. Digital radiography-based systems can offer the ability to view a sample while manipulating magnification, X-Y directions, rotation, tilt, and exposure. The advantage of digital X-ray over traditional film X-ray inspection is the improved imaging at magnification and the ease of image optimization.

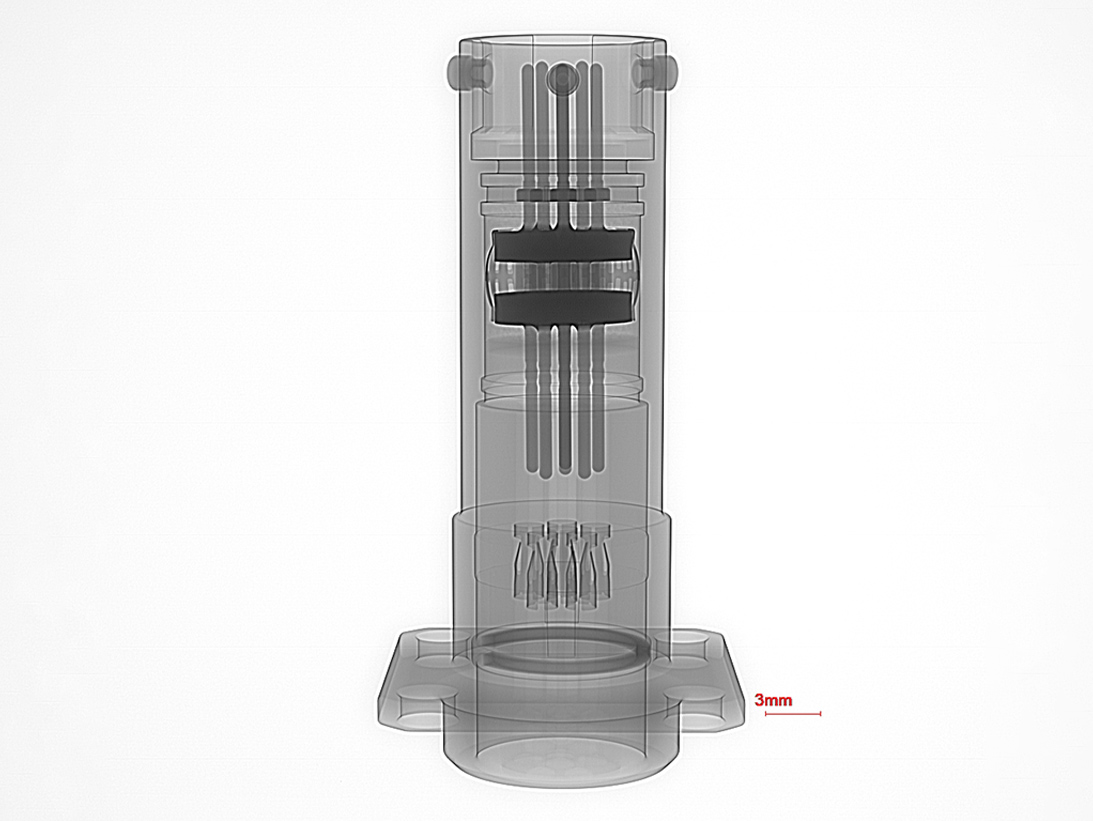

Actively inspecting a device under manipulation is known as “real-time radiography”. Real-time X-ray systems can be equipped to mechanically rotate a device in steps, through a defined angular sequence, while collecting individual exposures. The exposures are assembled into a 3-dimensional model, where thin slices of the device can be generated and viewed, or stitched into 3D renderings, referred to as Computed Tomography or CT-Scans.

ORS Inc. has five digital X-ray systems from leading X-ray manufacturers such as COMET YXLON, SEAGATE, NORTHSTAR and DAGE, each with unique platforms and technology, allowing versatility to provide the best possible inspection of your devices. ORS employs image quality indicators (IQIs) manufactured and certified in accordance with ASTM E-801. Our systems have the capability to resolve a feature less than 0.001” and are optimal for screening devices to Mil-Prf-19500 (semiconductor devices), Mil-Prf-38535 (integrated circuits), or Mil-Prf-38534 (hybrid microcircuits). All ESD training is compliant with ANSI/ESD S20.20-2014 and Mil-Std-1686. Inspection and verification of ESD areas is performed quarterly with a field meter and multimeter traceable to NIST standards making ORS well equipped for screening of live and flight parts.

ORS has over 40 years of experience providing quality X-ray radiography services to the microelectronic, semiconductor, PCBA, and aerospace industries. ORS X-ray inspection is DLA suitable for Mil-Std 883/TM 2012, Mil-Std 750/TM 2076, and Mil-Std- 202/TM 209.

Standards & Specifications

- MIL-STD-1580

- MIL-STD-883, TM 2012*

- MIL-STD-750, TM 2076*

- MIL-STD-202, TM 209*

- MIL-STD-981, APPENDIX B

- MIL-DTL-3933

- MSFC-STD-355

- ESCC 20900

- IDEA-STD-1010

- MIL-PRF-27, APPENDIX B

- ASTM E1161

- ASTM E431

*ORS maintains DLA suitability for these test methods

Capabilities

- Submicron spot size

- 130KV to 225KV range

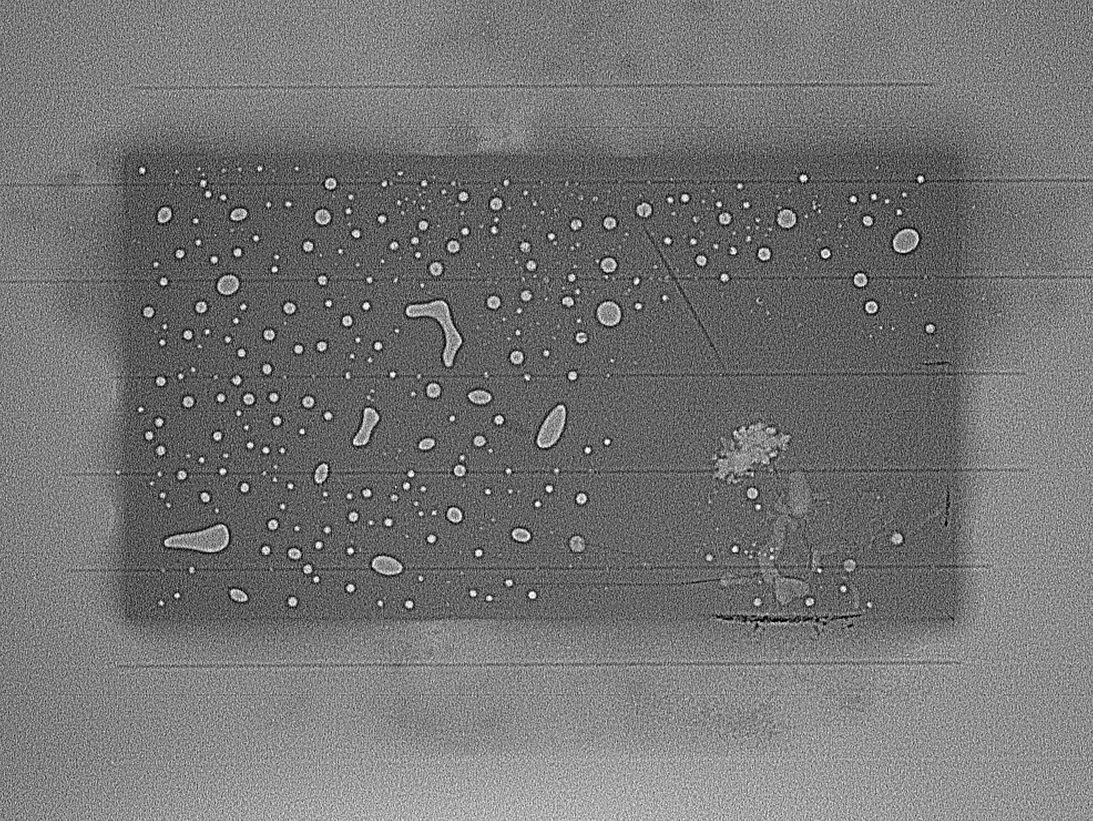

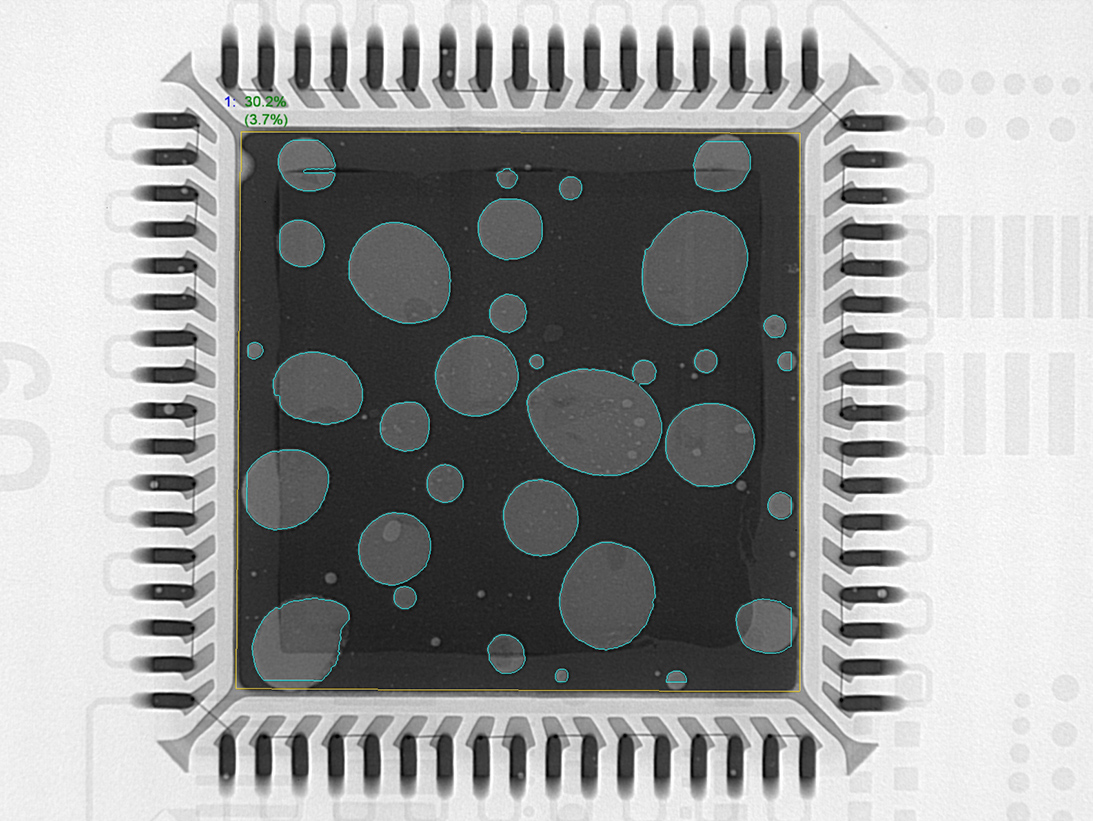

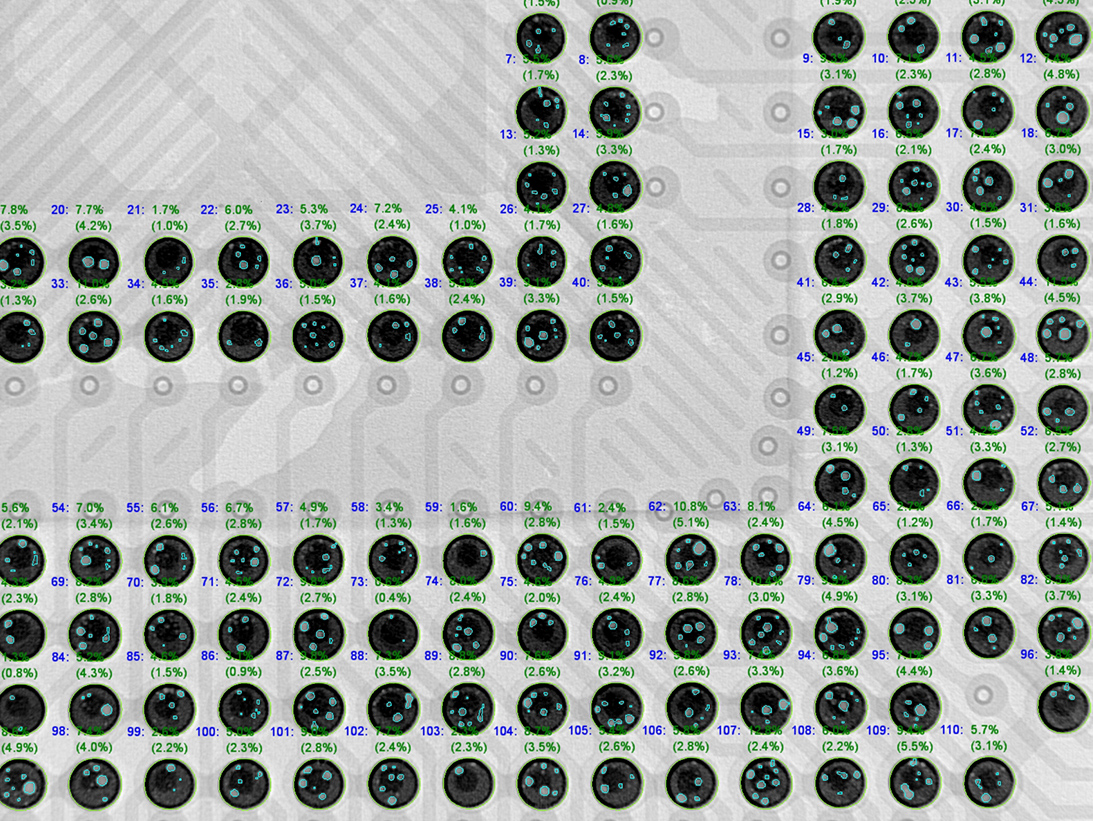

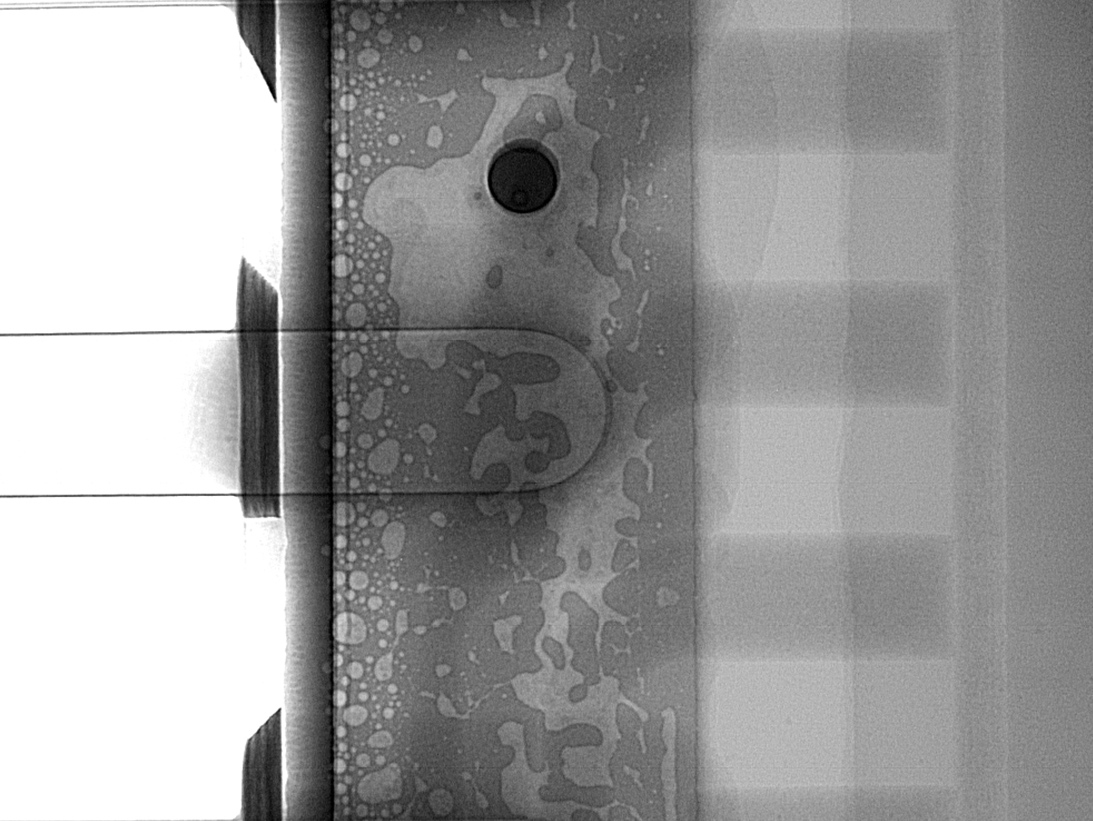

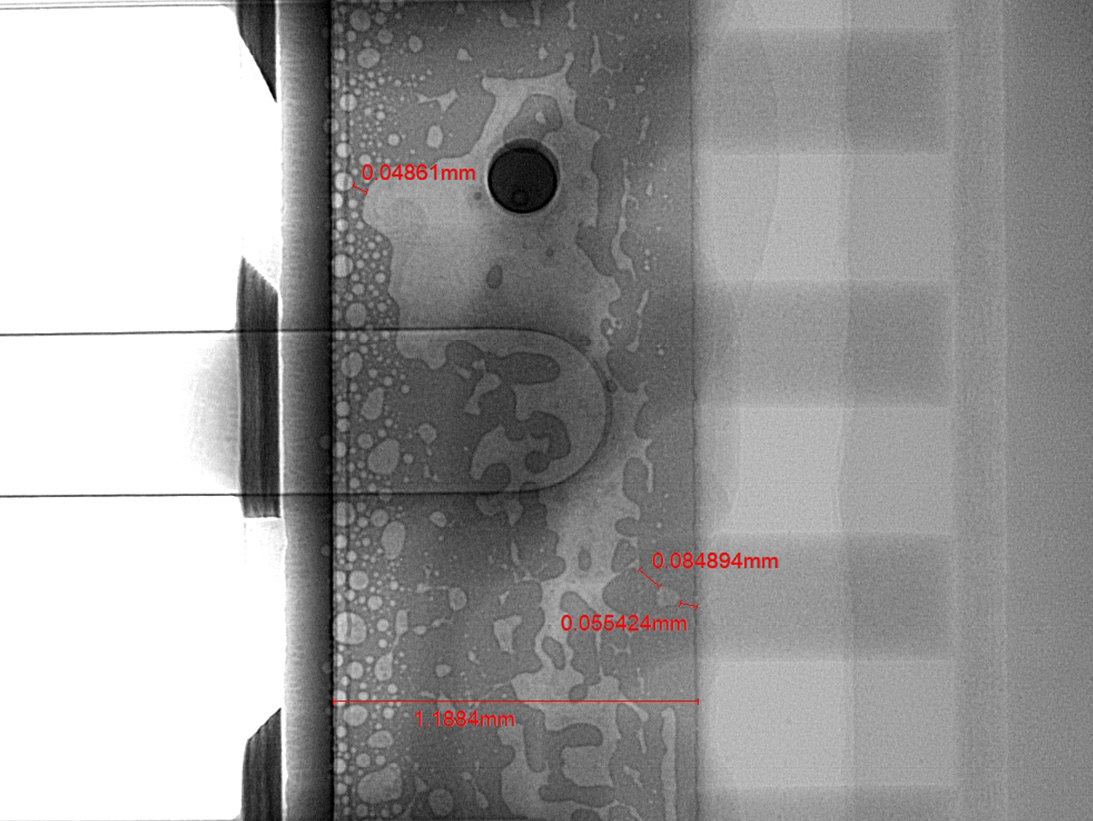

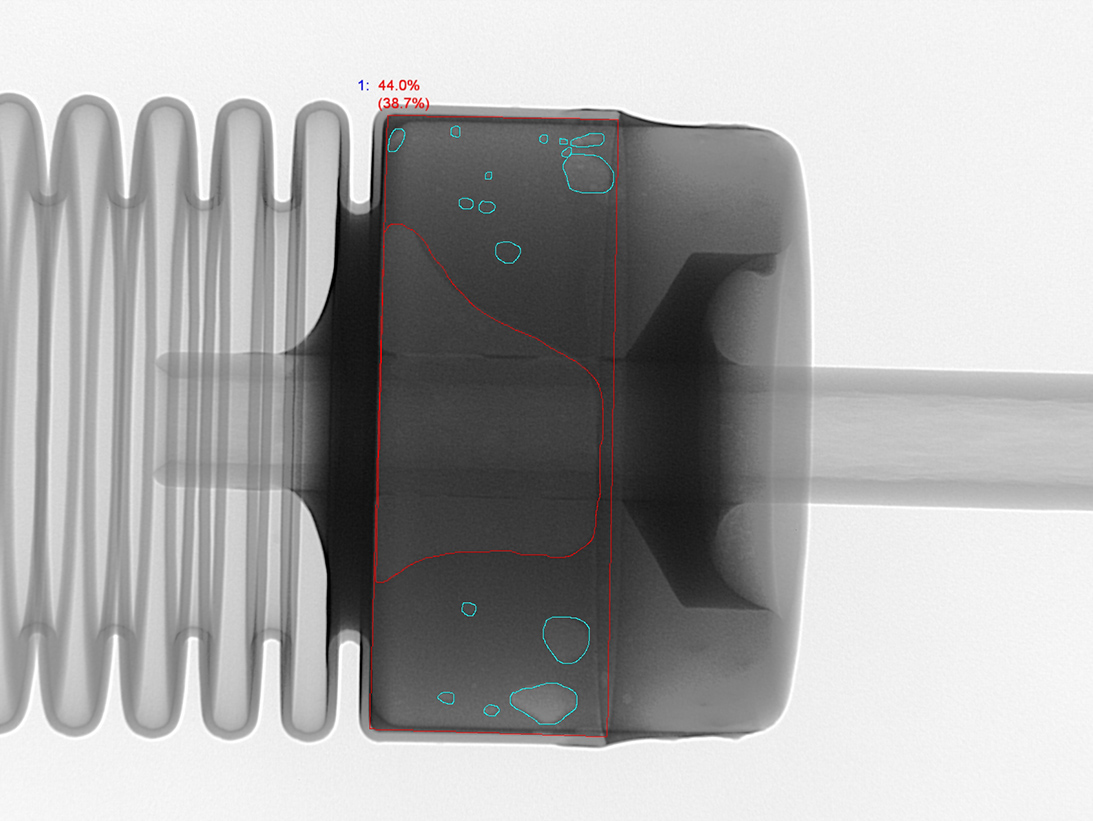

- Automatic void identification and measurement software

- Resolution less than 0.001” (1 mil)

- Image analysis and measurement software

- System (geometric) magnification up to 4800X (1400X)

- Oblique angle viewing 0 to 45 degrees

- Digital imaging

- Laminography

- Maximum inspection area of 18” x 16” (458mm x 407mm)

- Maximum stage weight of 11 lbs. (5kg)

ORS will also work with clients to develop a specific Statement of Work (SOW) curated to the client’s analytical needs and ORS’ capabilities

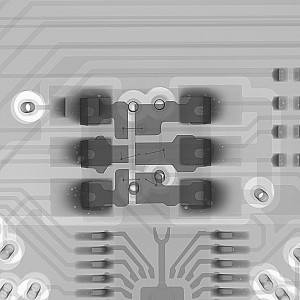

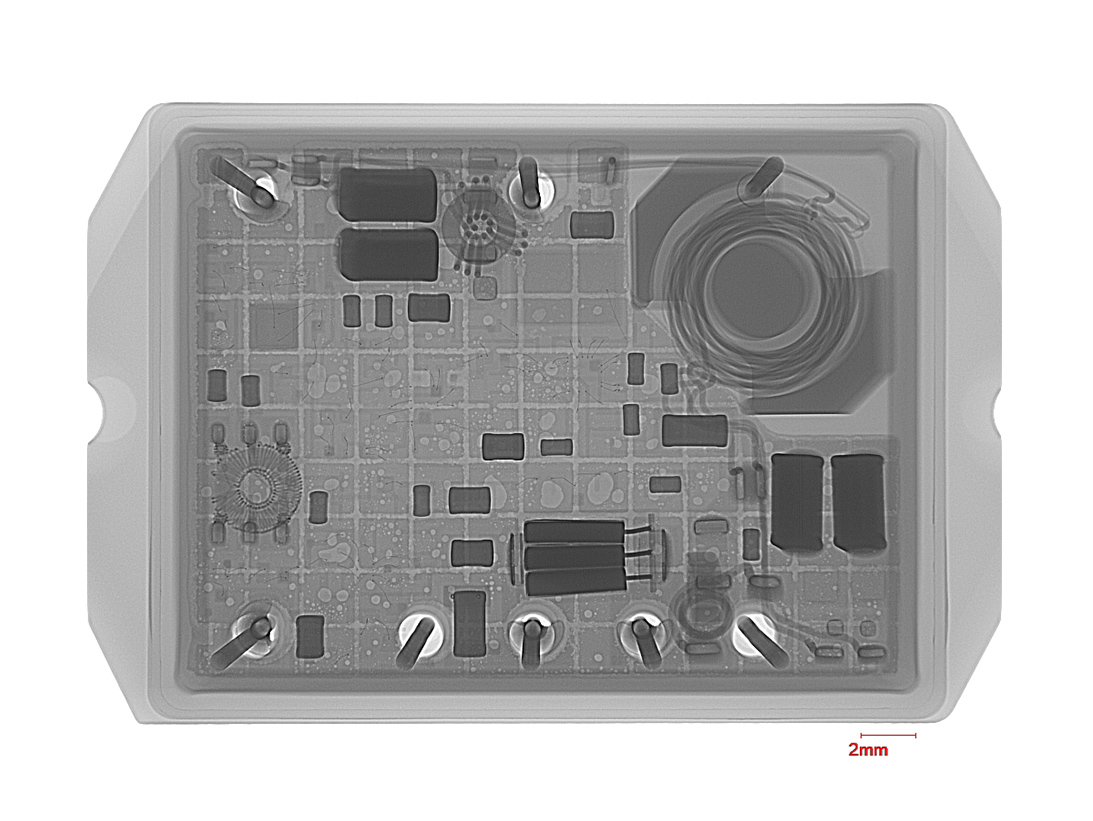

Printed Circuit Board

- Solder Joint Formation

- Metallization Defects & Registrations

- Via Alignment

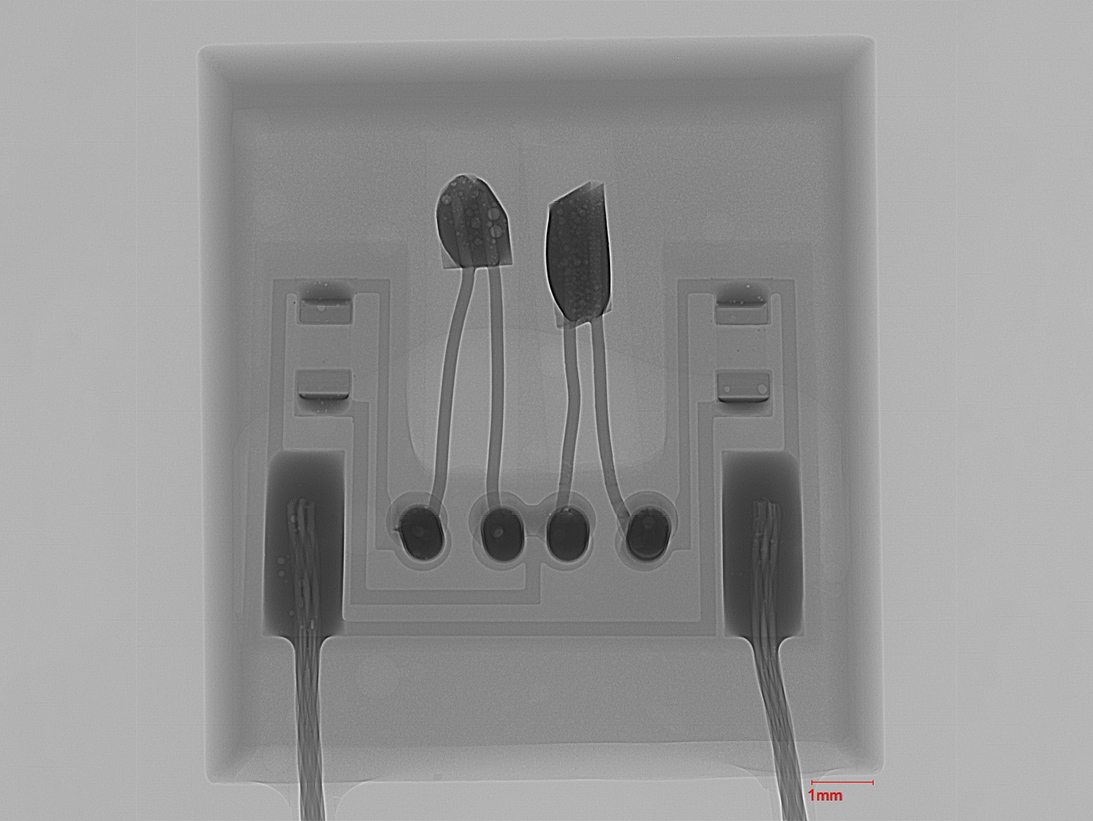

Ceramic Packages

- Frit Seals

- Foreign Material

- Die Attach

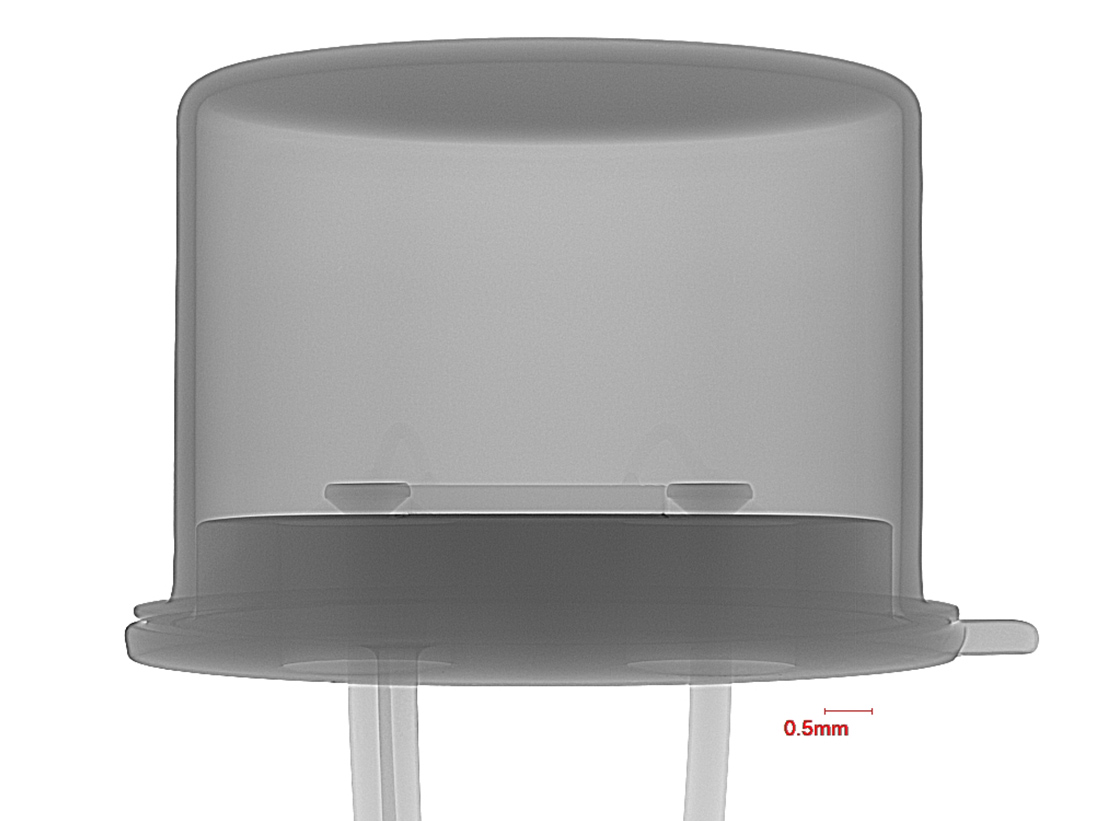

Metal Packages

- Lid Seals

- Die Attach

- Opaque Particles

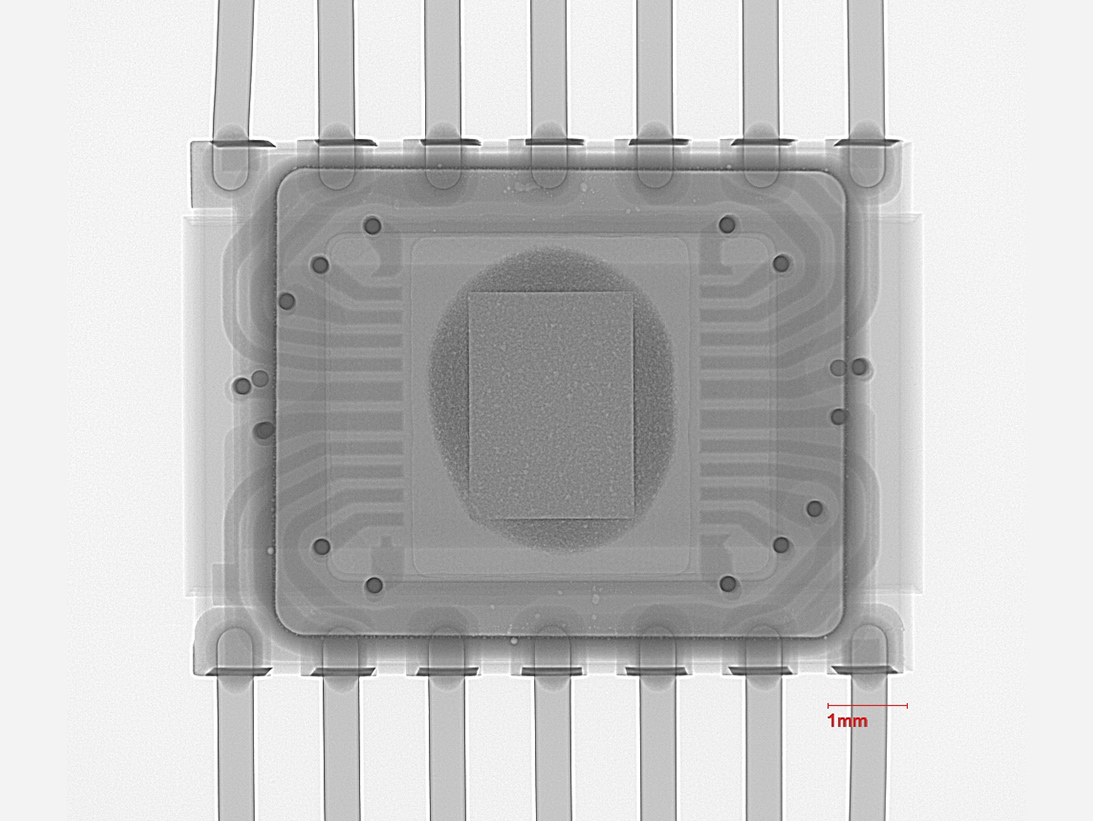

Plastic Packages

- Die Placement

- Die attach voiding

- Bond Wire Sweep

Ball Grid Arrays

- Solder Sphere Formation & Voiding

- Die Attach

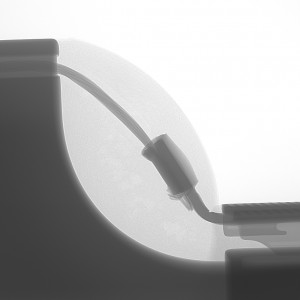

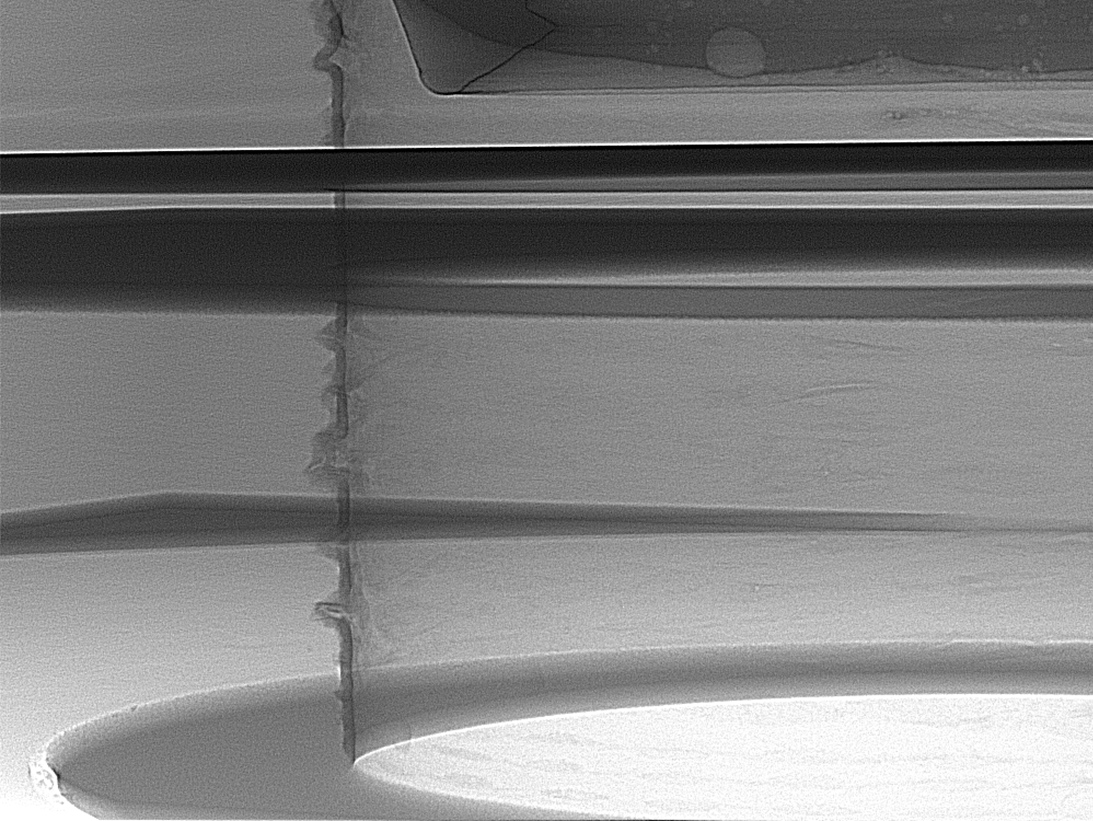

Failure Analysis

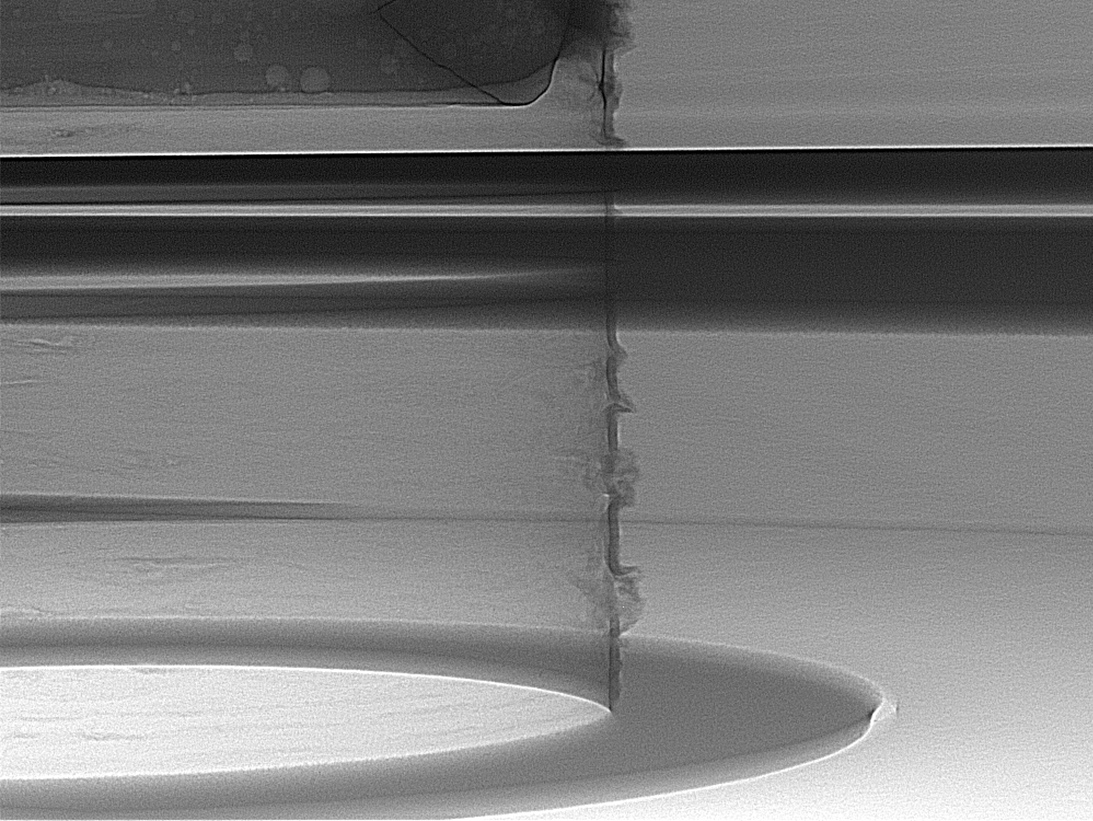

High voltage silicon carbide diode with severe EOS damage

Folds in the plated thru-hole barrel

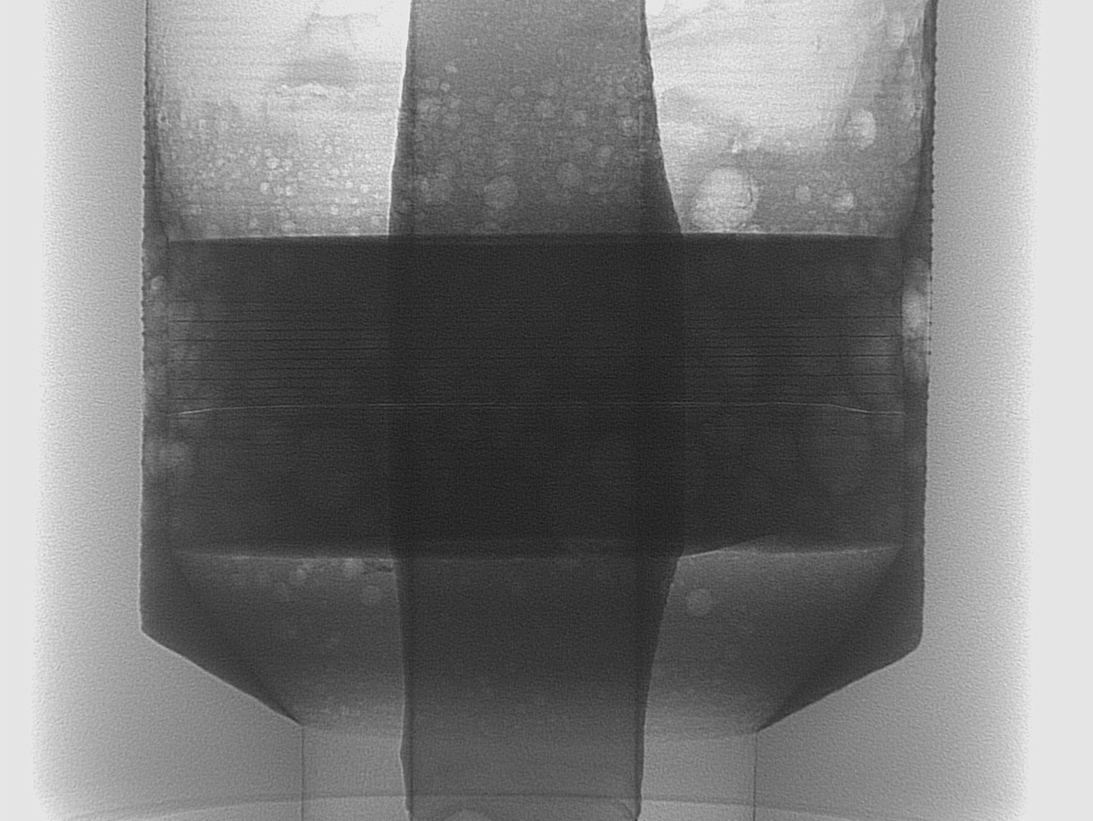

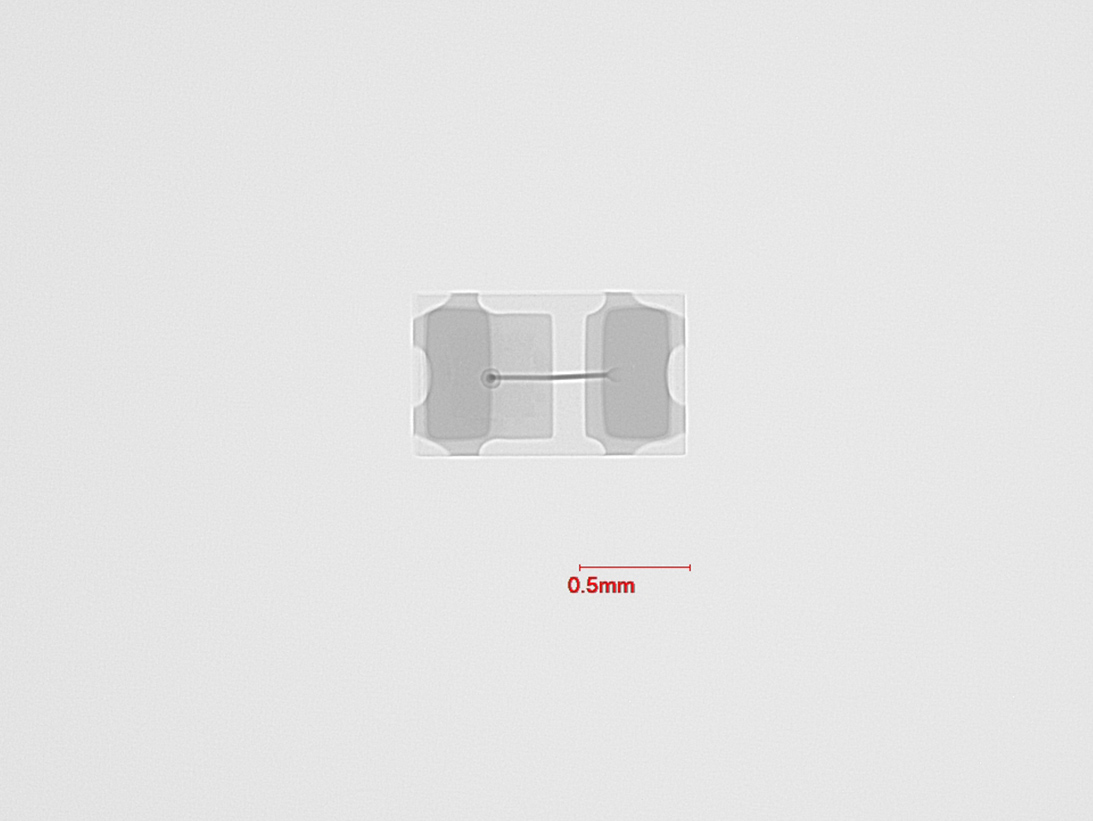

Crack in capacitor

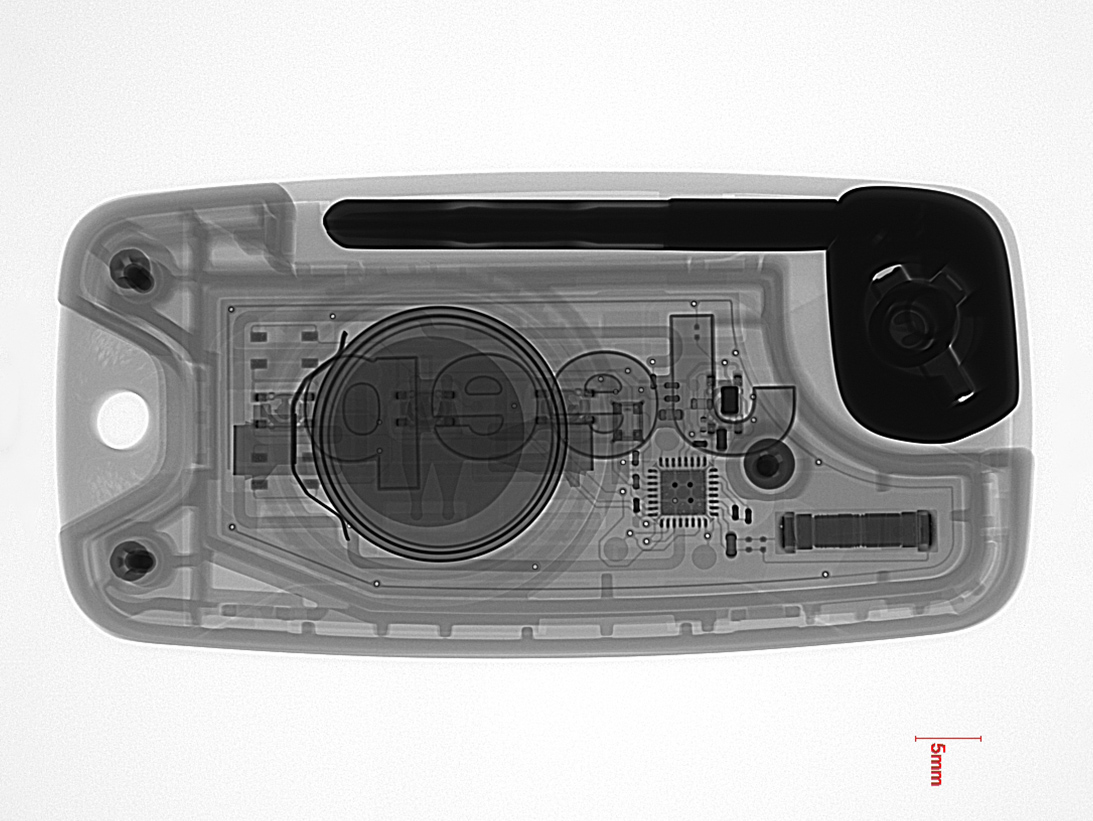

Non-functioning key FOB

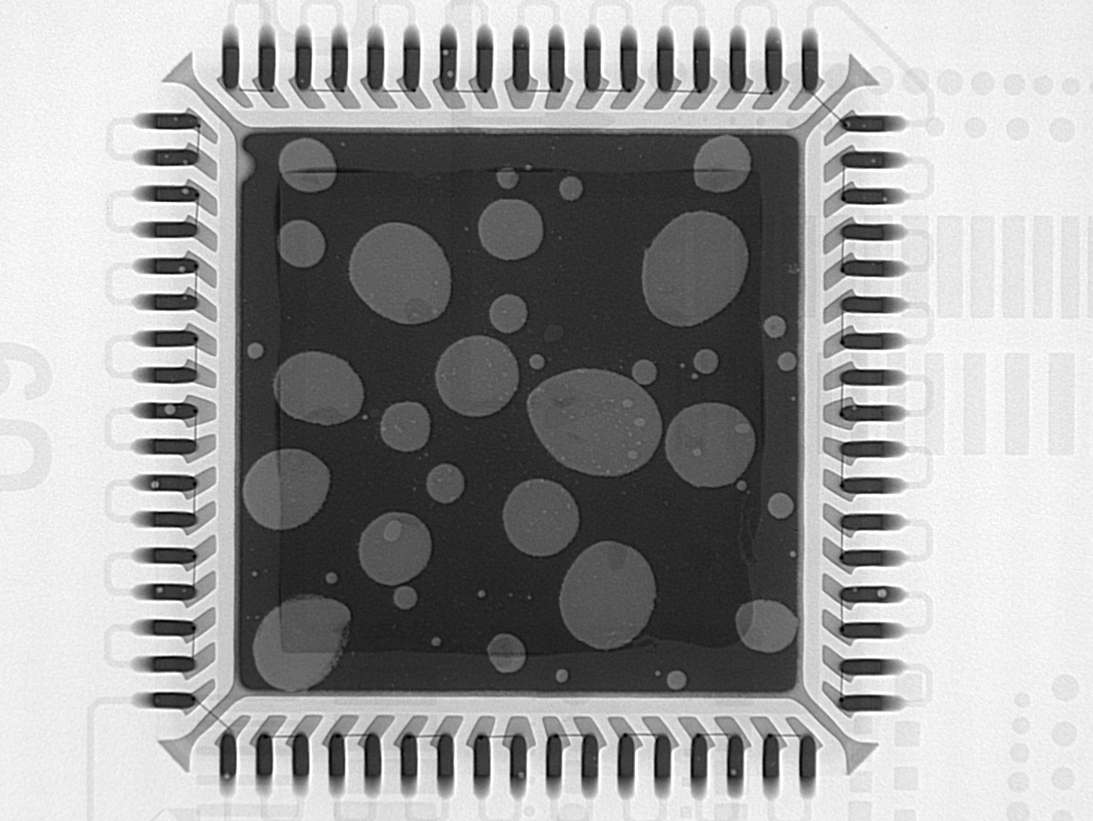

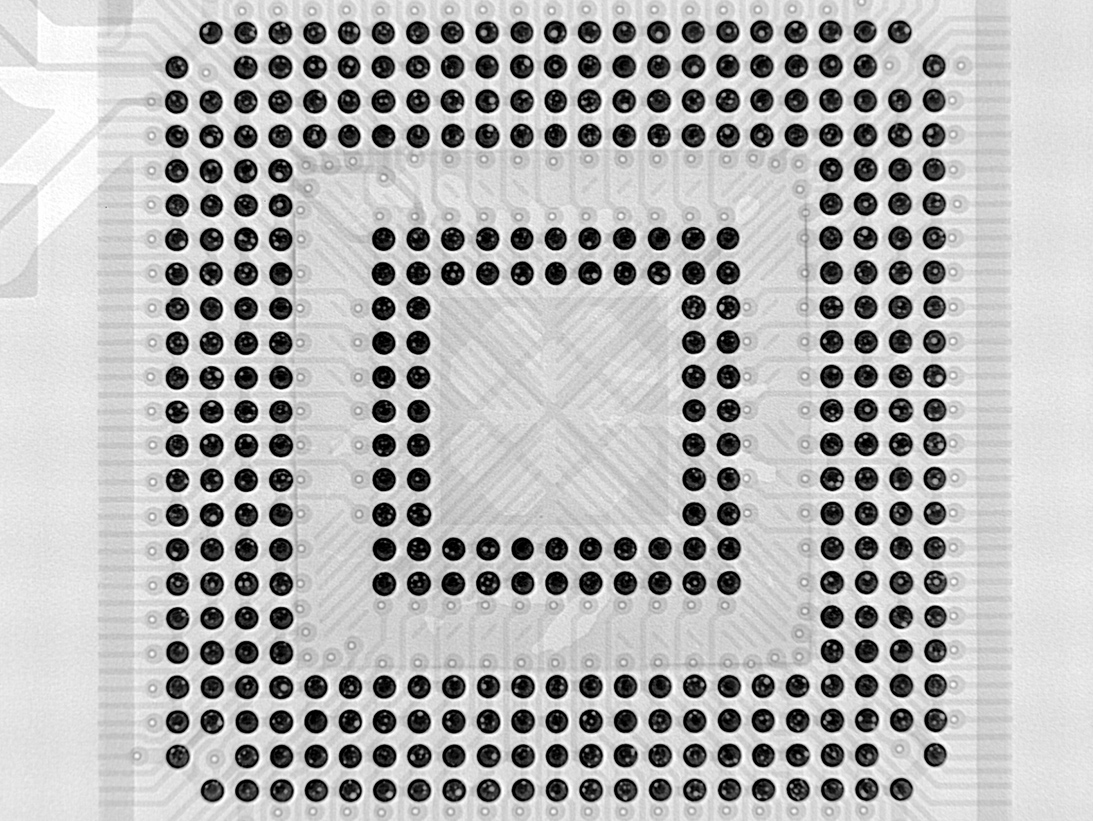

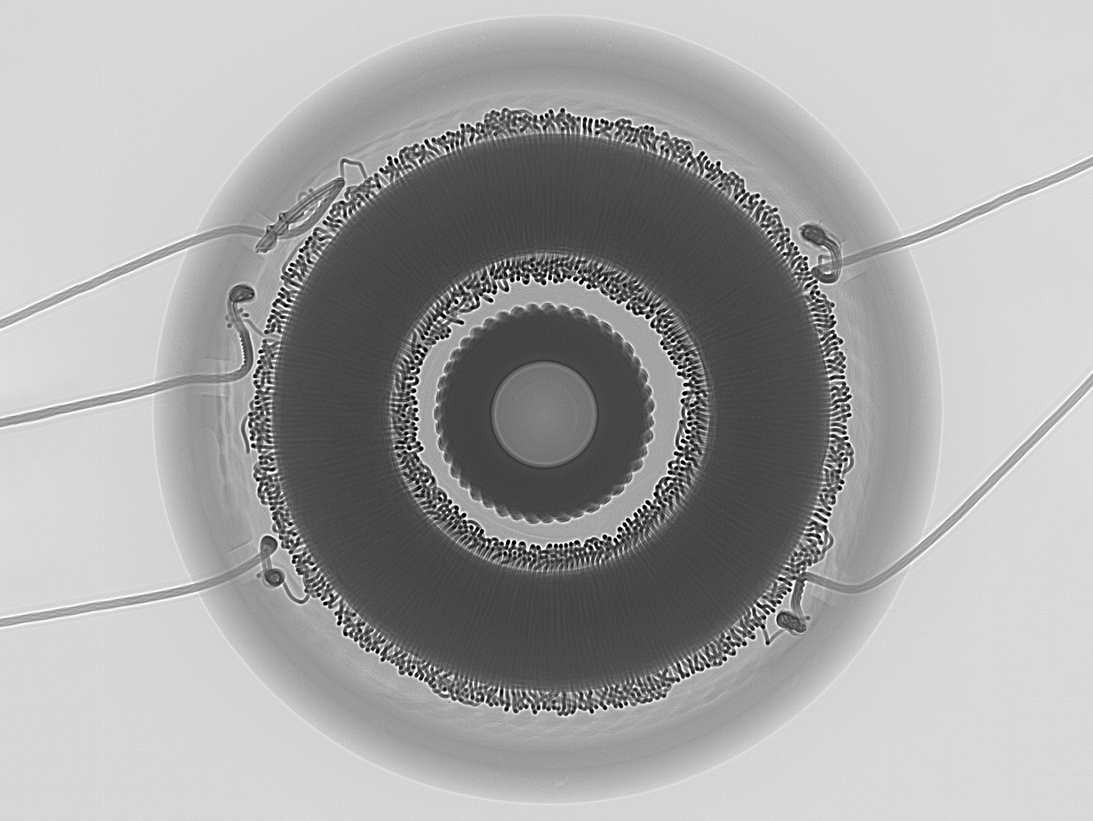

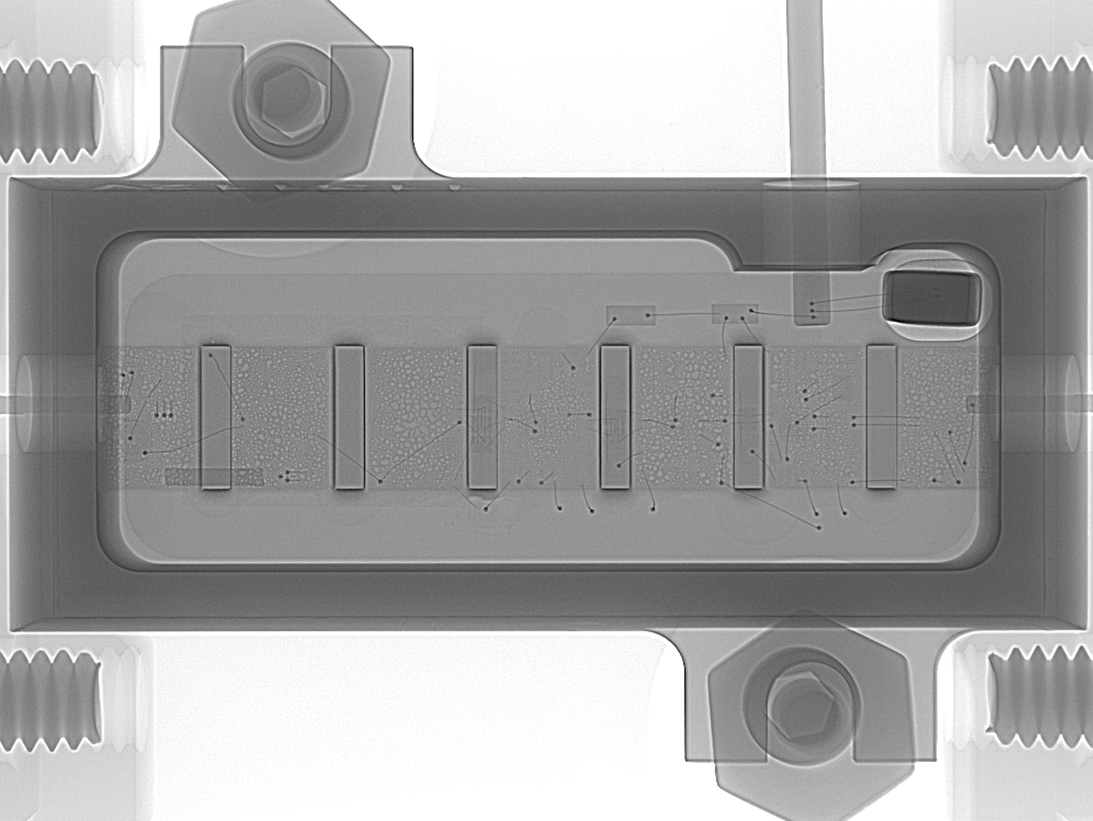

Void Analysis

Contact area voiding in QFN

BGA void analysis

Lid seal voiding in microcircuit

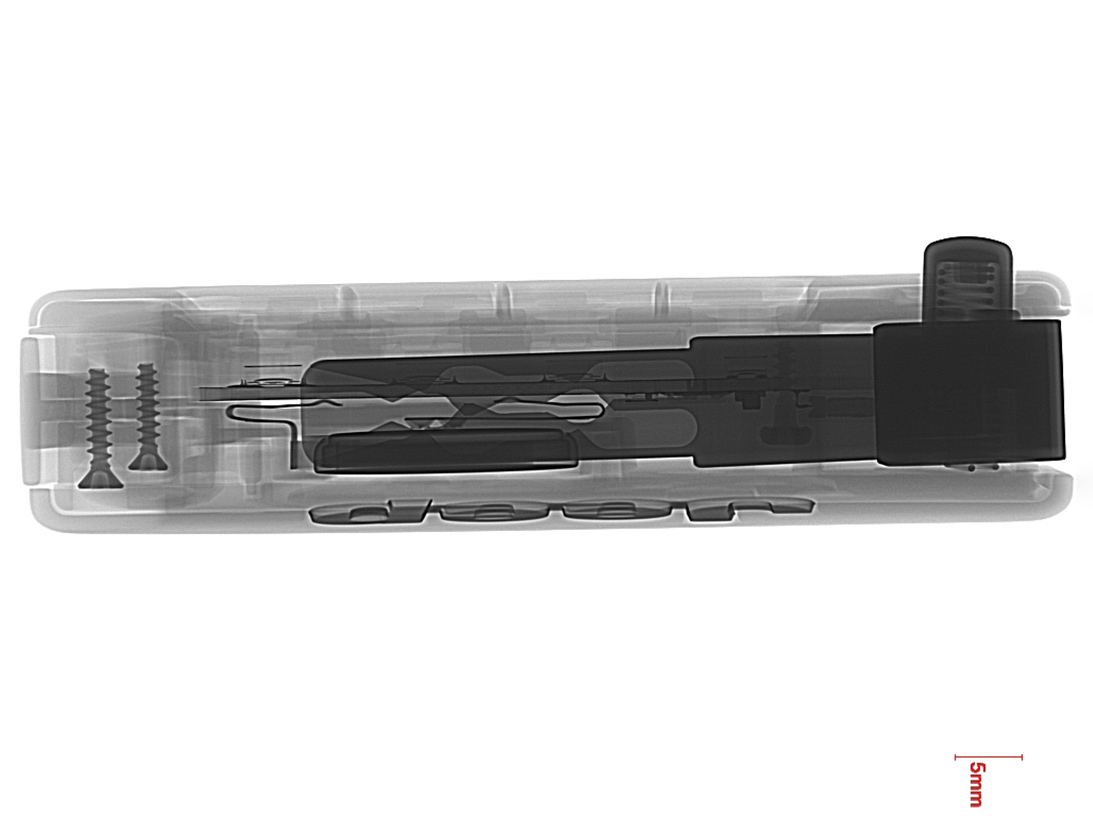

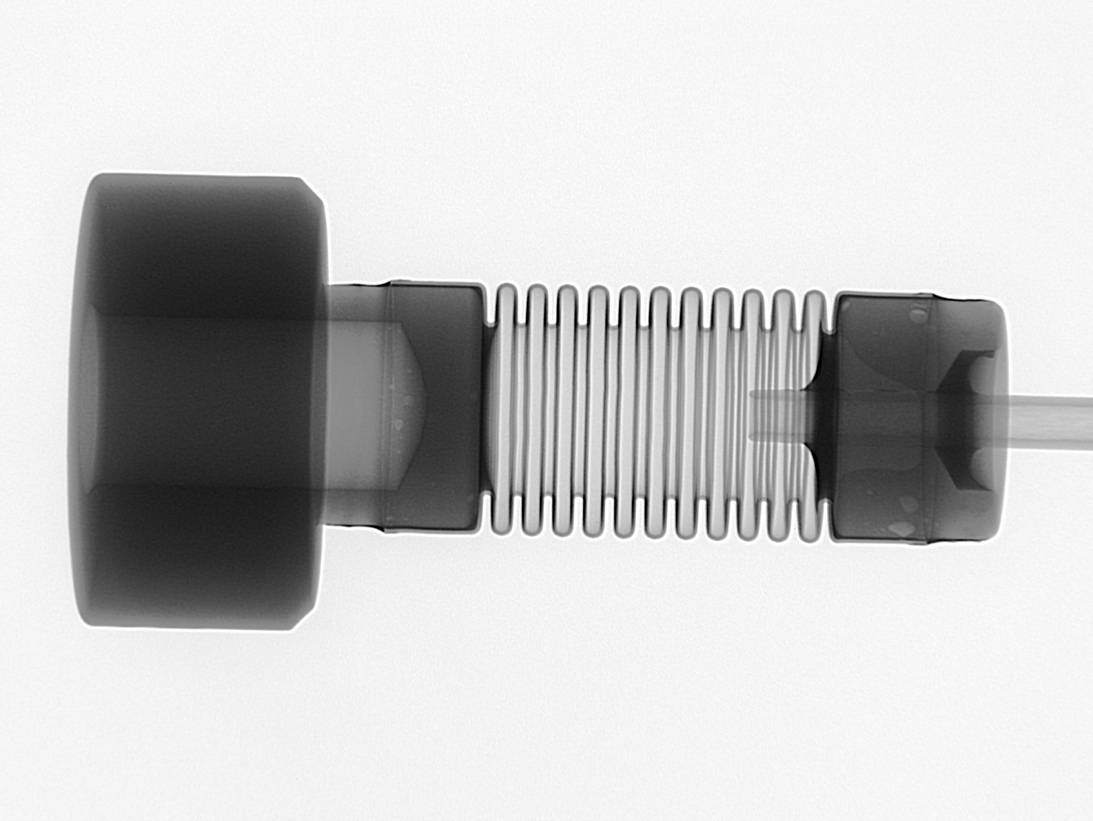

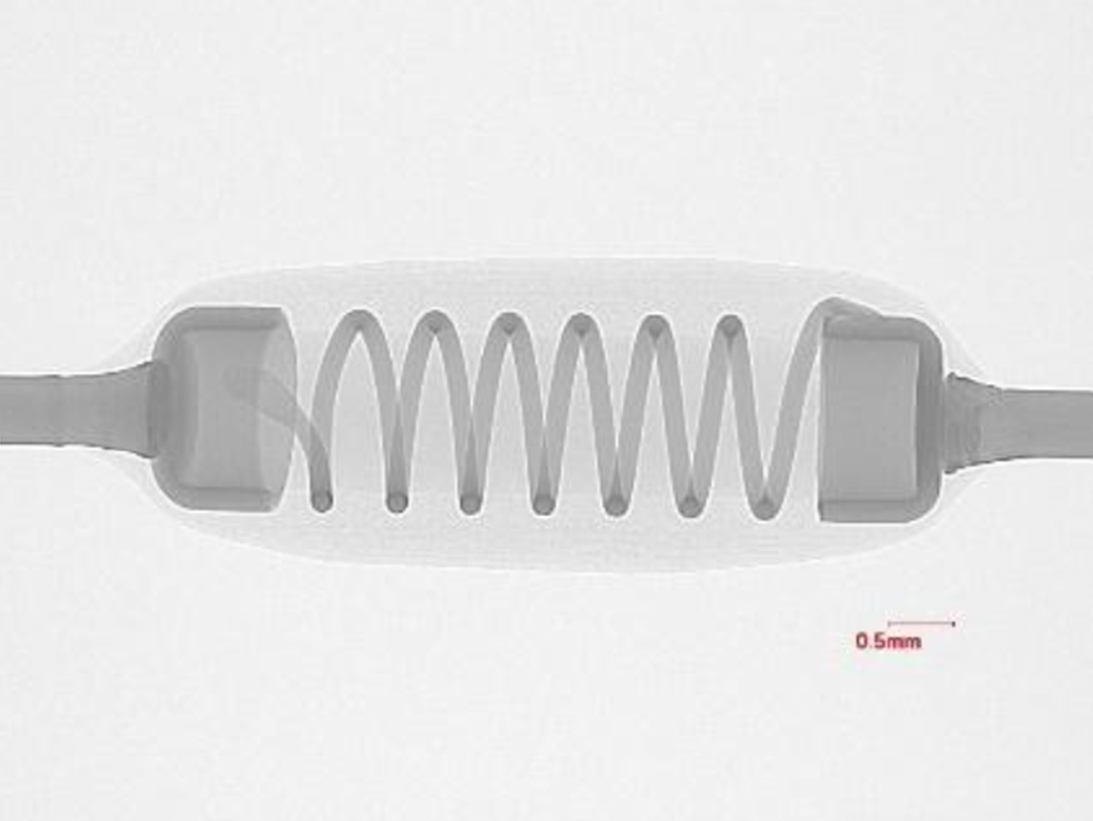

Bellows solder joint void analysis

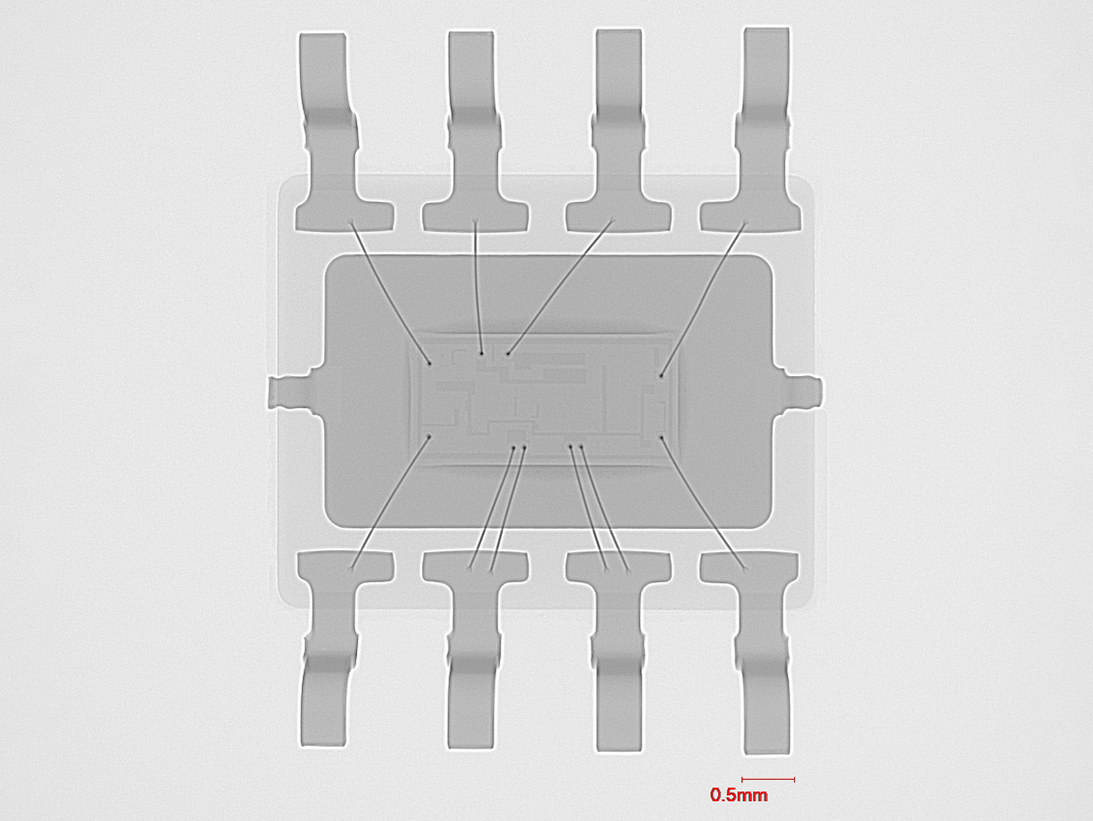

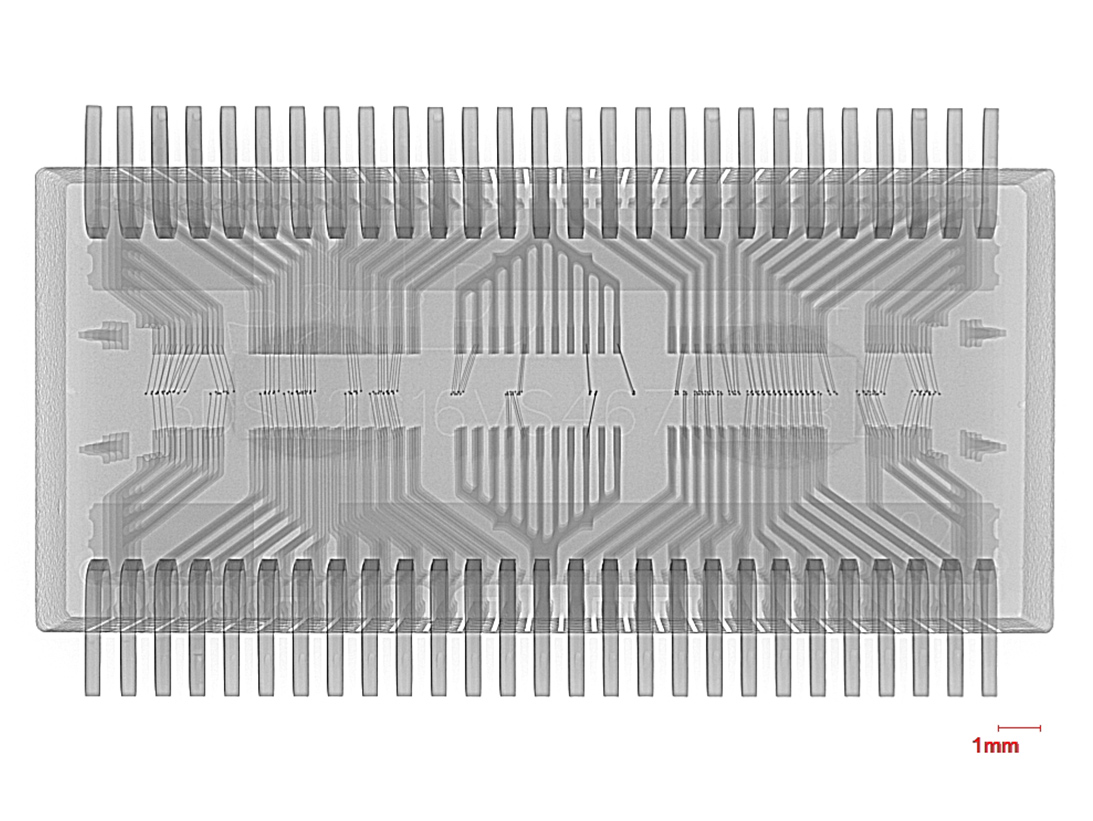

Electronic Part Types

Integrated circuit

Hybrid microcircuit

Attenuator

Transistor

Glass-bodied Diode

Thermistor

Crystal Oscillator

Inductor

Transformer

Amplifier

PEM

MCM

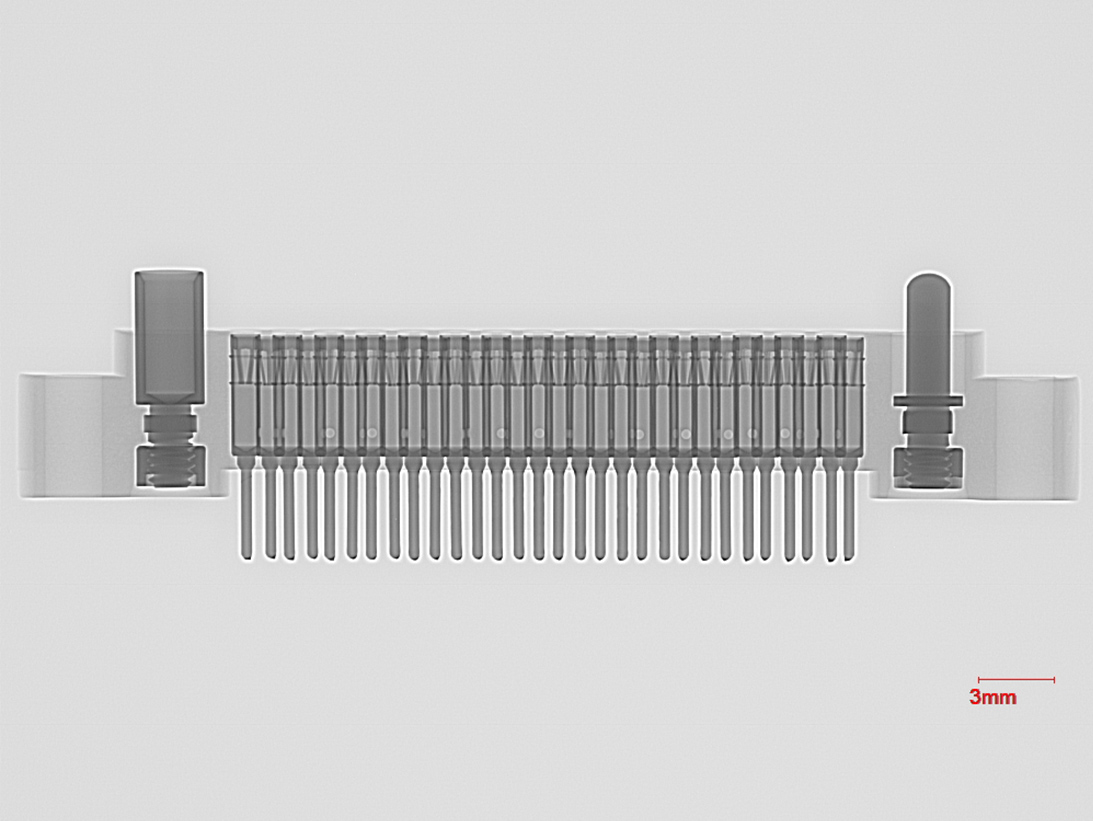

Multipin Connector

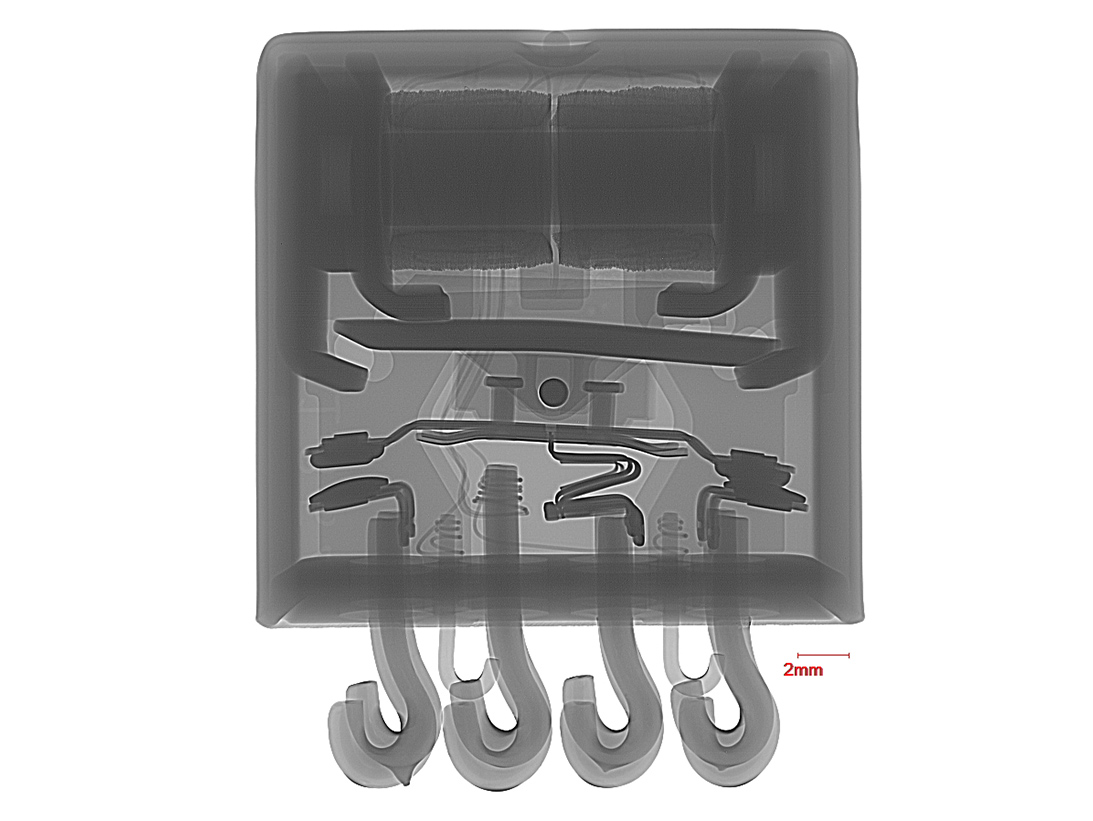

Relay

PED

Wire-wound resistor

Multi-anode tantalum chip capacitor

RF Connector

Other part types:

- DC-DC Converter

- Diodes (Thin key, Schottky, Wire-bonded, Zener voltage regulator)

- EMI Filter

- Isolator

- Quartz Crystal

- Bellows assemblies and sub-assemblies

- Optocoupler

- Filtered Connector

- Power Divider

- Resistor Network

- Fuse

- Switch

- PCBs