Materials/Surface Analysis

ORS offers a wide range of testing techniques for material analysis, process monitoring and failure analysis. Our laboratory staff has in-depth expertise in electronic components and modules, PCBs, metals, gases, organics and inorganics. Have questions? Our scientific staff can recommend the analytical technique that will best meet your requirements.

Micro Fourier Transform Infrared Spectroscopy(FTIR): FTIR testing is useful for identifying functional groups of small spot size organic contaminants found on surfaces as part of a full surface analysis test.

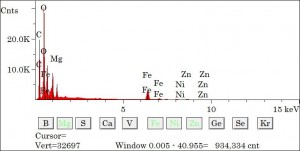

Scanning Electron Microscopy (SEM): During SEM analysis, the X-rays, characteristic of the area of the specimen being probed by the electron beam, allow both a qualitative and quantitative determination of the elements present in the selected region. High energy back-scattered electrons (BSE) can be separated and used for image formation. Since the back-scattering efficiency is a function of atomic weight, this image reveals compositional variations due to average atomic number.

X-Ray Fluorescence Elemental Analysis (XRF): The X-Ray Fluorescence technique uses high energy X-rays to excite the sample material then determines the material composition based on the radiation emitted, the process is similar to SEM/EDX.

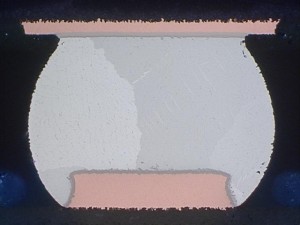

Ion Milling is a surface preparation technique that is used to aid in materials analysis. Ion Milling can provide distinguishable delineations in the surface topography of a sample.