Solderability Testing

Solderability testing provides a means of determining the solderability of device package terminations that are intended to be joined to another surface using SnPb or Pb-free solder. The procedure, considered to be destructive, tests whether the packaging materials and processes used during manufacturing operations produce a component that can be successfully soldered in the next level assembly.

There are two methods of testing device solderability:

- Method 1 is known as ‘dip and look,’ which is for leaded and leadless terminations. It includes preconditioning if needed, the application of flux and the immersion of the terminations into molten solder.

- Method 2 is a Surface Mount Simulation test.

Test standards MIL-STD 883 and J-STD-002 reference preconditioning for the purpose of assessing device package solderability. While optional, an accelerated precondition is generally used prior to package solderability testing to simulate package shipment and storage. These options, to be agreed upon between the user and the supplier, include steam conditioning or dry bake.

The inspection and failure criteria require:

- Removal of all flux prior to inspection of the terminal surface

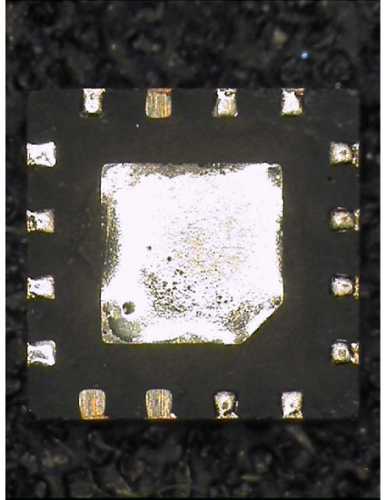

- Inspection of the devices at 10x to 20x magnification

- A minimum of 95% solder coverage of each lead within the inspected area